Three forces are colliding: sustainability (valorising agri-waste and lower-impact fibres), experience/design (novel sensory & storytelling hooks), and tech convergence (PCMs, luminescent additives, conductive yarns, living materials). Together they create materials that are not only more sustainable but also behave differently (heat-regulating, light-emitting, sensing), opening new product categories and marketing stories for textile brands.

What it is & where it comes from

Banana fibre (often sold as “banana pith”, “banana silk” or vaazhai naaru in South India) is extracted from the banana plant’s pseudostem — the part left after harvest. It’s a bast-type natural fiber whose physical character sits somewhere between linen and silk: natural sheen, good strength, breathable hand, biodegradable. Indian handloom houses and retail stores are already selling banana-fibre sarees and mixes (often blended with cotton or silk).

How it’s made (practical notes, production realities)

- Extraction: fibres are separated from the pseudostem by manual scraping, retting (biological/enzymatic softening) or mechanical extractors; newer semi-mechanized processes exist at research institutes and local units. The processes determine the fibre’s colour, softness and yield.

- Preparation: fibres are washed, dried, sometimes degummed/bleached, carded and spun into yarn; blends with cotton or silk are common to improve drape and reduce stiffness.

Sourcing & pilot idea (actionable)

- Source small blind sample lots from NE Indian cluster producers or cottage units (NEIST has extraction tech documented). Produce a 3-SKU summer capsule (scarves, lightweight kurta, blouse) as a limited “Banana Silk” drop with clear provenance storytelling.

Cons & cautions

- Cost & scale: small-scale production today means variable quality and sometimes higher unit cost vs commodity cotton.

- Technical finishing: raw banana fibre can be coarse; finishing (softening, blending) is often essential for mainstream RTW comfort.

What it is & origin

Lotus fibre (often called lotus silk) is made from the delicate fibres inside lotus stems. It’s historically produced in Myanmar and parts of Southeast Asia; modern niche producers in Cambodia, Vietnam and small Indian workshops also experiment with it. Because extraction is extremely labour-intensive and yield per plant is tiny, lotus silk is a luxury/novelty material — very high price per metre.

Production realities

- Fibre must be pulled strand-by-strand, dried and spun by hand; the labor intensity explains the price and artisanal positioning. Expect small, handcrafted batches rather than mill production.

Design & retail angle

- Positioning: ultra-premium, culturally resonant (lotus symbolism), vegan “silk-like” alternative for ceremonial pieces. Use for a hero saree or limited shawl/luxury scarf series.

Caveats

- Scaling impossible at commodity price. Use as a halo product — high margin, storytelling heavy, not for mass assortment.

What exists today (commercial reality)

- There are commercially available phosphorescent (glow-in-the-dark) embroidery threads made by established thread manufacturers (polyester filaments embedding phosphorescent pigments). They recharge under light and glow for hours; many are advertised as washable and machine-embroidery compatible. These are ready for production and low technical risk.

How they work (simple tech)

- Phosphorescent threads embed glow pigments (often strontium-aluminate-based) in a polymer filament; they store light and emit it slowly after dark. More experimental routes include electroluminescent fibers or conductive textiles powering LEDs/EL strips (needs power), and cutting-edge bioluminescent approaches that actually use living organisms.

Care & regulation notes

- Check washfastness claims, laundering temperature limits and local chemical/REACH equivalents — glow pigments are robust but performance varies by supplier. Always get wash-cycle test data.

What this is

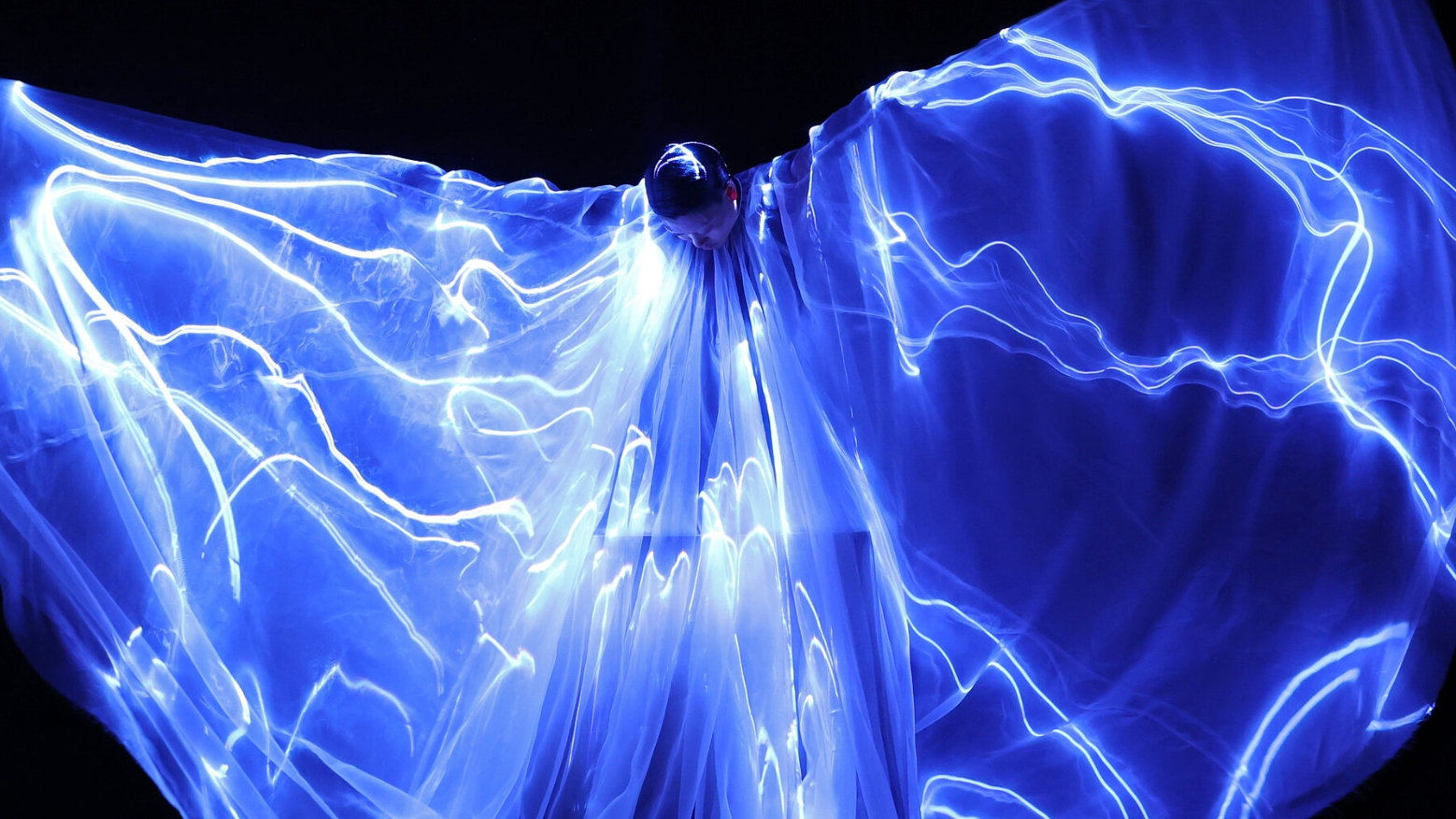

Bioluminescent fashion uses living organisms (algae, bacteria) or engineered proteins to produce light. Recent couture experiments (not yet consumer products) — e.g., Iris van Herpen’s algae-based glowing garments — show the aesthetic and symbolic potential but also the fragility and care challenges of living materials. These are spectacular for runway and PR but not yet retail ready.

Major hurdles

- Durability & safety: maintaining living organisms needs humidity/nutrients and raises biosafety and regulatory questions.

- Commercial readiness: current projects are lab-to-runway; significant R&D and bio-ethics oversight are required before retail.

Practical use for brands

- Don’t try mass retail yet. Use living bioluminescent pieces as installations, capsule shows, or museum/gallery collaborations. If you want store theatrics, pair phosphorescent threads (safe, washable) with a single living couture piece for PR.

How “heat-regulating cotton” actually works

- Two commercial approaches dominate: (A) Phase-change materials (PCMs) microencapsulated into coatings or fibers (Outlast® is the best-known brand — originally NASA tech) that absorb/release latent heat around target temperatures; and (B) dynamic surface treatments / smart finishes (evaporative or radiative cooling finishes) that change surface behaviour to feel cooler. Both approaches are used to make garments that feel cooler/warm depending on conditions.

What the science says (performance & limits)

- PCMs can reduce peak microclimate temperature and improve comfort, but their “window” is limited to the melting/freezing temperature of the PCM and loading levels. Recent peer-reviewed work continues to improve encapsulation, stability and wash durability. Expect measurable comfort benefits but not “thermostat control” — think: meaningful comfort uplift rather than magic cooling.

Sourcing & quality checks

- Ask suppliers for independent thermographic testing, PCM loading %, number of wash cycles tested, and whether PCM is in-fiber (higher durability) or coating (higher loading but lower next-to-skin suitability).

State of the tech (lab → early market)

- E-textiles now range from embroidered conductive traces and washable sensors to flexible, woven conductive yarns and textile displays. The research base and small-scale commercial products exist; the market is growing fast (estimates show strong CAGR for smart textiles). But many solutions still require detachable batteries or non-textile components — fully integrated, washable, and mass-manufacturable e-textiles are still maturing.

What’s possible right now (real product ideas)

- Health & sports: ECG/HR sensor shirts, diabetic temperature-monitor socks, posture-sensing sleeves.

- Comfort & heating: integrated heating layers (Loomia style) with thin batteries and LEL (no rigid PCB) for outerwear.

Operational caution (manufacturing & aftercare)

- Washability & repairability are the main consumer hurdles — ensure component modularity (detachable batteries), clear wash labels, and defined warranty/repair routes. Work with experienced e-textile manufacturers for encapsulation and safety testing.

Sustainability, ethics & supply-chain governance (cross-cutting)

- Trace the feedstock: banana & lotus claims are only credible if stems are sourced sustainably and extraction doesn’t create a new monoculture or exploit labour. Use provenance stories and cooperative partnerships.

- Chemical footprint: PCM microcapsules, phosphorescent pigments and finishes have chemical profiles — request SDS, ecotoxicity and wash-off testing.

- Labour & benefit capture: craftspeople extracting lotus or banana fibre must be paid fairly; design supply chains that share premium margins.