Gone are the days when printing fabrics meant time-consuming block or screen processes. Today, digital printing is revolutionizing the textile industry with speed, precision, and unlimited design possibilities. From vibrant fashion prints to personalized home décor, digital printing is redefining creativity.

What is Digital Textile Printing?

Digital textile printing is the process of directly applying designs onto fabric using digital inkjet technology, similar to how a home printer works — but with specialized inks for textiles.

✔ Key Features:

- Prints designs directly on fabric (no intermediate steps like screens)

- High-resolution images (up to 1200 DPI)

- Works on natural and synthetic fabrics

Feature

Setup

Cost

Colors

Time

Traditional Printing

Requires screens or blocks

High for small runs

Limited per screen

Lengthy setup

Digital Printing

No screens, just digital files

Cost-effective for small runs

Unlimited color combinations

Fast, on-demand production

Direct-to-Fabric (DTF)

- Prints design directly onto the fabric surface.

- Best for cotton, silk, viscose, polyester blends.

Sublimation Printing

- Transfers design via heat on polyester-based fabrics.

- Perfect for sportswear and activewear.

Reactive & Pigment Printing

- Uses reactive dyes for natural fibers and pigments for versatility.

Why Digital Printing is the Future

- Unlimited Design Options: From photo-realistic images to 3D effects.

- Eco-Friendly: Uses less water and chemicals compared to traditional methods.

- Cost-Effective for Small Orders: Perfect for customization and limited editions.

- Faster Time-to-Market: Designers can print and launch collections within days.

Fashion

Sarees, dresses, co-ord sets,

scarves with bold prints.

Home Furnishing

Cushion covers, curtains,

upholstery with digital artwork.

Personalization

Custom prints for niche markets

and influencer collections.

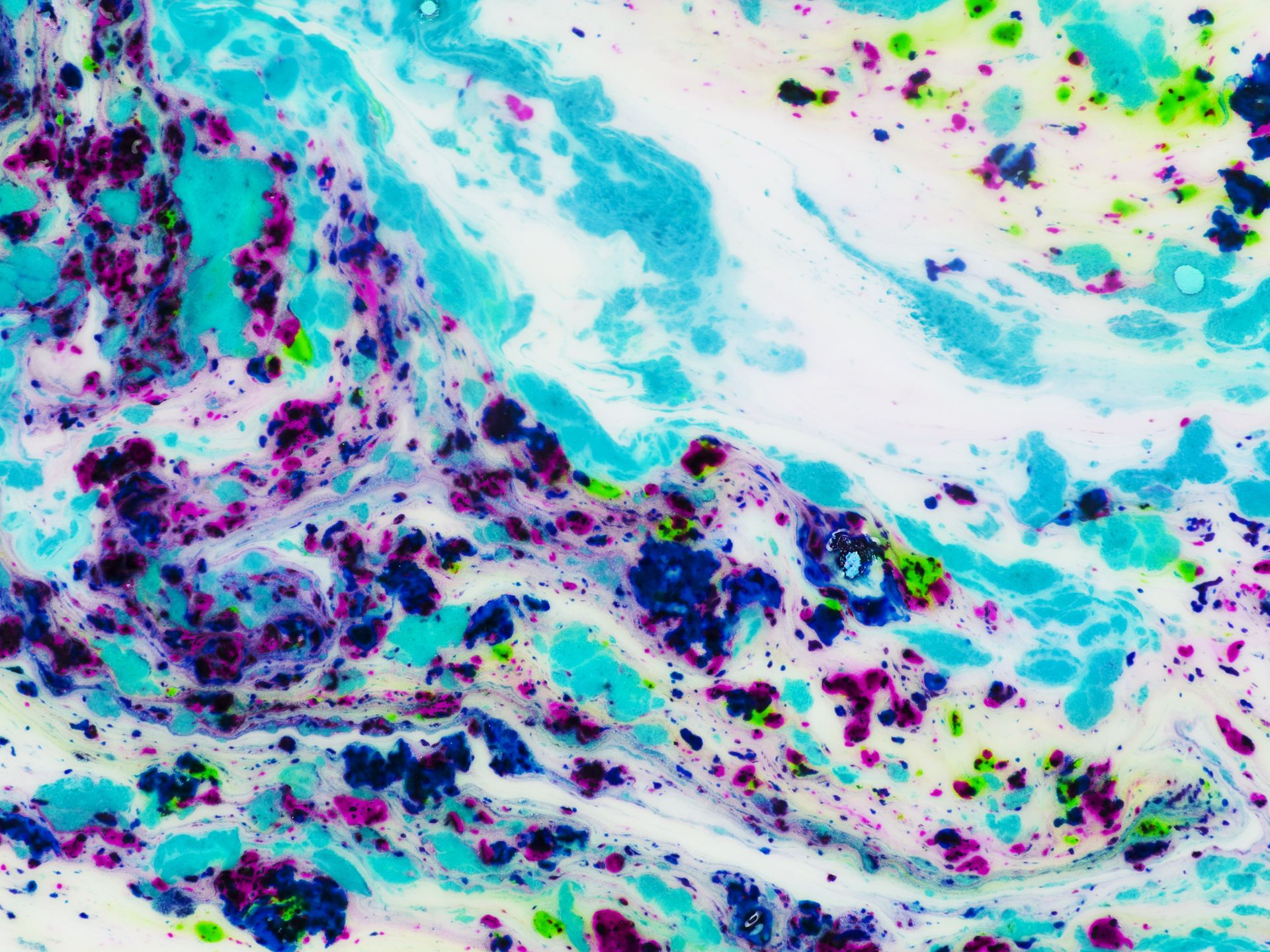

3D Effect Prints

Photographic Landscapes

on satin and georgette

Hybrid Techniques

(Digital + Metallic Foil)

Eco-Inks

for sustainable collections